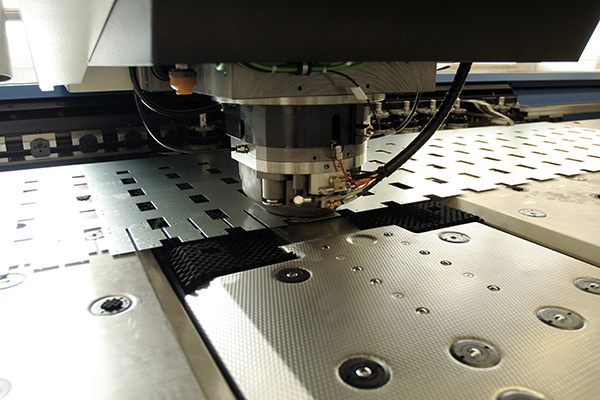

CNC Turret Punch Press

What is a CNC Turret Punch Press?

A CNC Turret Punch Press is a machine that punches a variety of shapes at a specified size out of sheet metal. The holes can be of different shapes, such as circles or squares. The machine works on an XY axis and runs at a high speed, and is best used when you have a project that requires a large number of holes.

Upon receiving a drawing, we map out the most efficient way to cut out your parts from sheet steel. Many forming applications can be incorporated right into the fabrication process reducing cost by boosting efficiencies and eliminating secondary operations

Benefits

Cost-effective: Low to no tooling cost – we have a large catalog of tooling on hand to produce accommodate whatever project comes our way

High productivity: With 300 hits a minute, this machine is great at producing a high quantity of holes in a short amount of time.

High efficiency: Precise, and through proper design, we limit the amount of scrap produced.

What Types of Materials Can Be Used?

It is a very versatile machine. Any metal or material can be punched up to a certain width. Depending on the material, we can go up to ¼ inch.

Why Choose GLPS?

GLPS technicians are expertly trained and know how to run the punch press efficiently and cost-effectively, saving you time and money. The majority of our products are proudly made in the U.S.A.*

*All of our manufacturing, assembly, and finishing is completed in the U.S.A from high-quality metals and other raw materials, the majority of which are also made in the U.S.A. From time to time we may source steel and other metals from Canada or other countries to offer our customers lower prices or where particular metals are not manufactured in the U.S.A. If having a product “all or virtually all” made in the U.S.A. is important to you, please let us know and if we can complete your order with entirely made in the U.S.A. materials, we will be happy to do so. We can also provide certificates, showing the place of origin of the metal, if requested at the time your order is placed”.