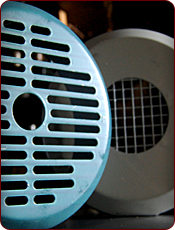

A manufacturor of electric motors, a client of Great Lakes Pressed Steel Corporation, needed 120 fan covers annually for one of their product lines. This precision metal stamping project highlights our metal drawing capabilities.

Composed of 18 gauge sheet steel, the raw material was first cut to a manageable size on our shear. Custom metal stamping and drawing created a finished part that measured 8″ to 16″ in diameter, at a depth of 4″ to 6″. Our precision processes allowed us to maintain tolerances of ±0.010″, even with the extreme drawing that this product required. Once we had the tooling in hand we were able to manufacture this fan cover in 2 to 3 weeks, with new tooling requiring lead times of 8 to 10 weeks. For more information on this project see the table below or contact us directly.