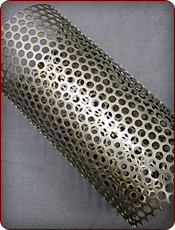

A customer in the heat exchanger industry needed a specially fabricated strainer to be used in a Rolairtrol air separator. Composed of 304-stainless steel, the strainer would measure 3.125″ in outside diameter, be 0.0235″ or 24 gauge thick, and meet tolerances of +0.000″/-0.062″. Strainer lengths would vary from 8.750″ to 27.500″, to allow the product to be used in seven individual models of air separators. Fabrication required the shearing of the raw stock to a size that would accommodate the rolling process. After rolling, the strainers were spot welded and deburred. Each part was also subject to stringent quality control measures throughout the manufacturing process. We currently fabricate 1,000 of these strainers for this customer annually, with lead times of 7 days. For more information on this project, see the table below or contact us directly.